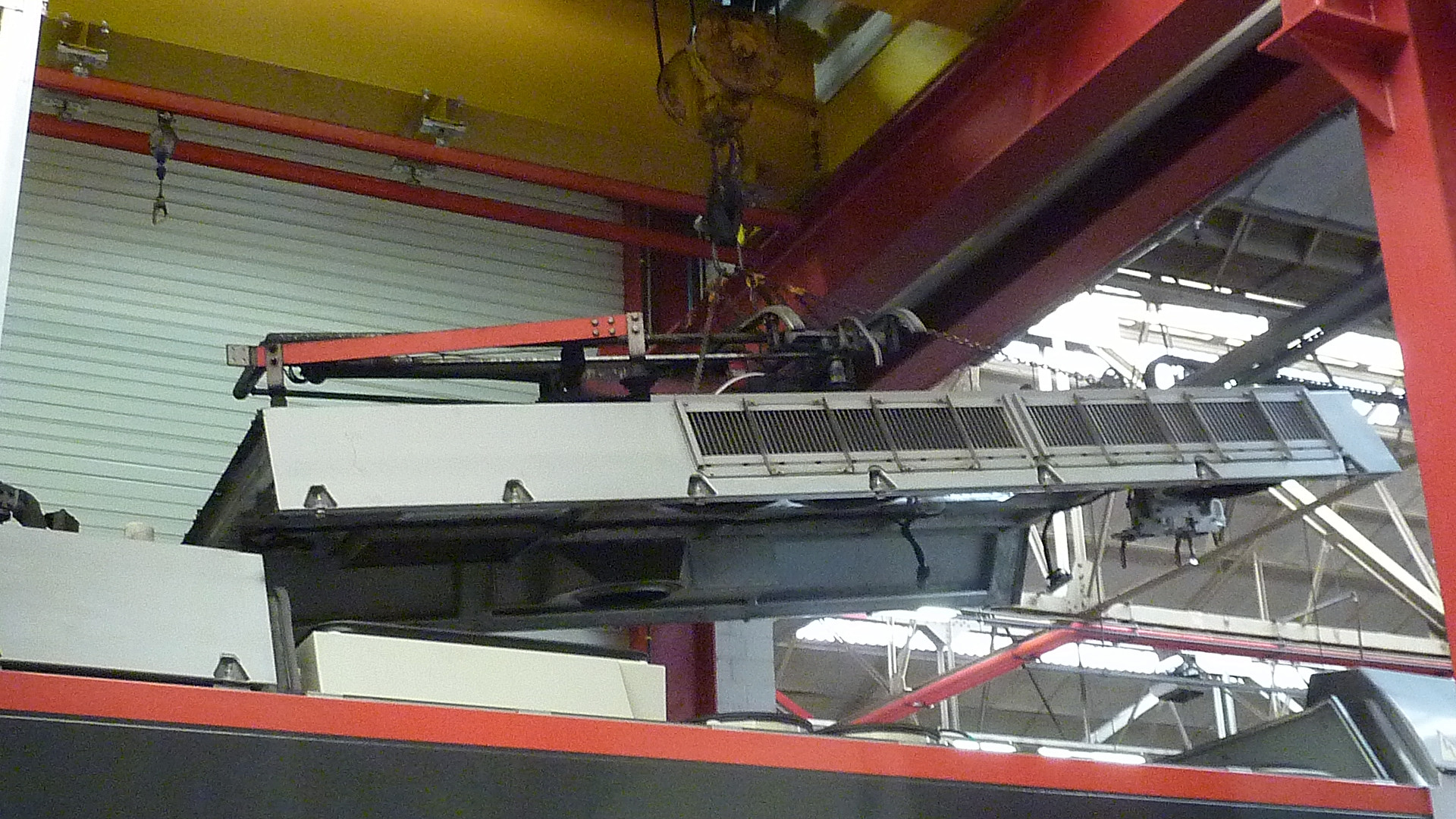

picture 1: DEMAN Custom Roof Panel Lifting Beam

B-Rail (N.M.B.S.) informed us about the difficulties they had in handling the roof panels of the SIEMENS HLE18.

The problem is that all locomotive roof panels are different. They all have 4 attachment point, but located on a different position. The centre of gravity varies for each different type of panel.

B-Rail tried a standard adjustable lifting beam (see picture 2), but it was not possible to handle the panels safely. So they started using chains (picture 3), but handling the panels horizontally remained impossible. Needless to say that this complicates the smooth positioning and fitting of the roof panels.

Last year, B-Rail invited us to design and build a custom lifting beam, solving all their problems.

Our engineering department developed a flexible, adjustable lifting beam for this purpose.

The hook positions are set up individually as well as the eye suspension. This allows to position the centre of gravity exactly under the eye suspension and crane hook. The manual adjustments are resulting in a perfect horizontal handling position for each type of roof panel.

And of course in a safe working condition and a smooth installation on the locomotive. In turn, this results in significant time savings and less damage cases.

The design of our “Custom Roof Panel Lifting Beam” can be adapted to fit other types of roof panels. Contact Kurt Deman on deman@deman.be for further information.

Picture 2: Standard Adjustable Lifting Beam

Picture 3: Handling of roof panels with chains

Picture 4: DEMAN Custom Roof Panel Lifting Beam with eccentric centre of gravity