More than 60 years of crane construction

Constructiewerkhuizen DEMAN NV has more than 60 years of experience, in building reliable and competitive lifting systems, which will help to increase the performance of your company.

Always and everywhere, DEMAN sets its standards very high. We strive to deliver the best possible quality , from the analysis design to production and customer service.

The day of today, there are almost no lifting technology solutions on the market, which cannot be found at DEMAN. Our know-how is a major plus-point, which you can utilize in your production process.

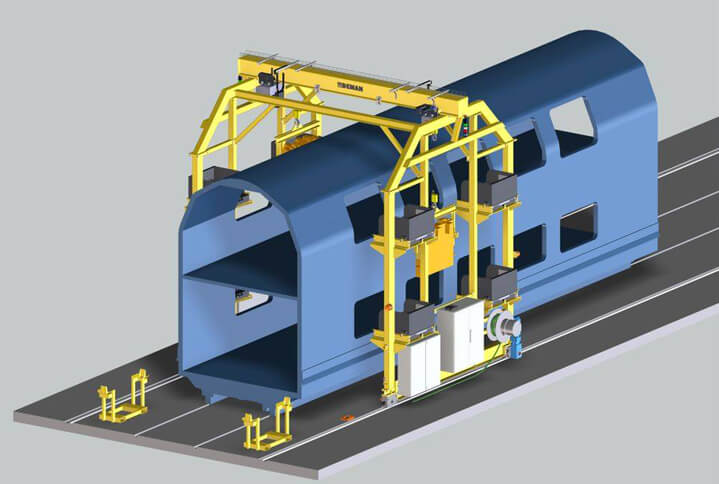

Engineering

Our creative team of experienced engineers and designers understands your specific needs.

This team, which stands in direct contact with you, will make a thorough analysis of your needs, which will be the basis for an optimally adapted solution.

We have built up an extensive know-how, in more than 60 years of building cranes, which ensures that you will dispose over a reliable, innovative and high-performance hoist.

Our in-house design office makes it possible for us, to fit all hoists perfectly into your infrastructure, even if the equipment should only be in the design phase. With the overall designs that are prepared in a 3-D format, we can exclude conflicts and evaluate safety risks. This manner of working together (possibly also with external consultants) is a guarantee for success from the very start!

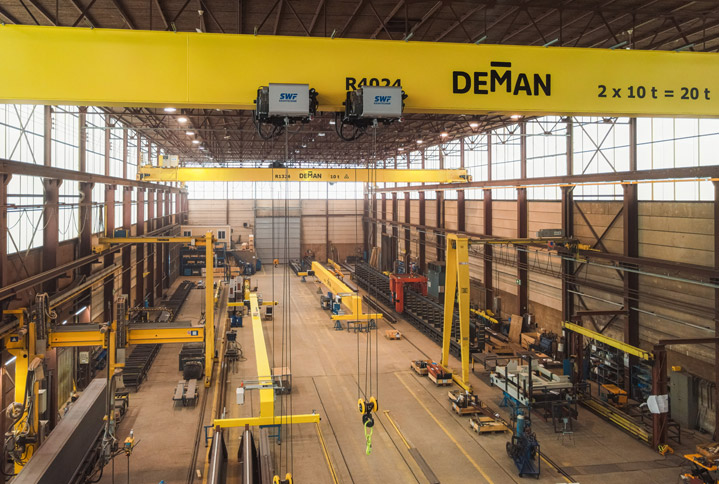

Production

Local production by a motivated team, which has years of experience, offers the possibility of working very flexibly, thereby permitting the integration of different local services and goods. This makes us the ideal partner, for co-productions with specialists selected by you, for instance for automation, bulk handling, etc.

The way we work and the quality we produce are guaranteed by conformity to different DIN and European standards, including among others EN-1090. But you can convince yourself of that quality, by simply paying a visit to our production sites. You will notice that we continuously strive for innovative and cost-effective production processes, with an integrated quality assurance.

Mounting

An expert assembly of a hoist is an essential and necessary step, in order to achieve a safe and troublefree operation. This is true both for the hoist itself, and just as much for the crane gantries, on which the overhead cranes and portal cranes operate. If the assembly is carried out precisely according to plan, then abnormal wear and tear is as good as excluded. The reliability and the operating life of the hoist is substantially improved thereby. and unexpected downtimes are reduced to a minimum.

The precision (measuring) tools, and the modified accessories that are used by our technicians, make an efficient and safe assembly possible. Safety is a primary requirement, also during the assembly, and this is an entirely implemented according to the requirements of a Contractor's Safety Checklist (VCA) certificate.

Service

You require an optimal availability of your hoists, namely a minimum of unexpected downtimes. Expert preventive maintenance at regular intervals is a (legal) requirement. And no one is better suited for this than our technicians, who do nothing else, year after year, and who benefit from permanent training.

And with our REMAIN programme, we keep track of all parameters and make sure that you benefit from substantial savings on the operating costs. In addition, you can also make use of our 24/7 emergency intervention service, which will solve even rare problems in no time at all.

Tracking via our REMAIN programme was started up in 2001. In the 15 years of its existence it has become perfectly clear that regular and expert preventive maintenance drastically reduces the number of unwanted downtimes. In addition, many remedial maintenance measures are not carried out after an unwanted failure, but usually on a good moment that has been planned far in advance, ensuring a minimum of hindrance to the production process.

Sustainability

“Moving to Green” is the name of a dynamic process, which was started up by DEMAN in 2010.

We successfully achieved a reduction of our ecologic footprint, through all kinds of actions that fall into three main areas:

- Energy savings

- Limiting emissions

- Sustainable products

If you wish to have more information about currently planned actions, do not hesitate to contact us.