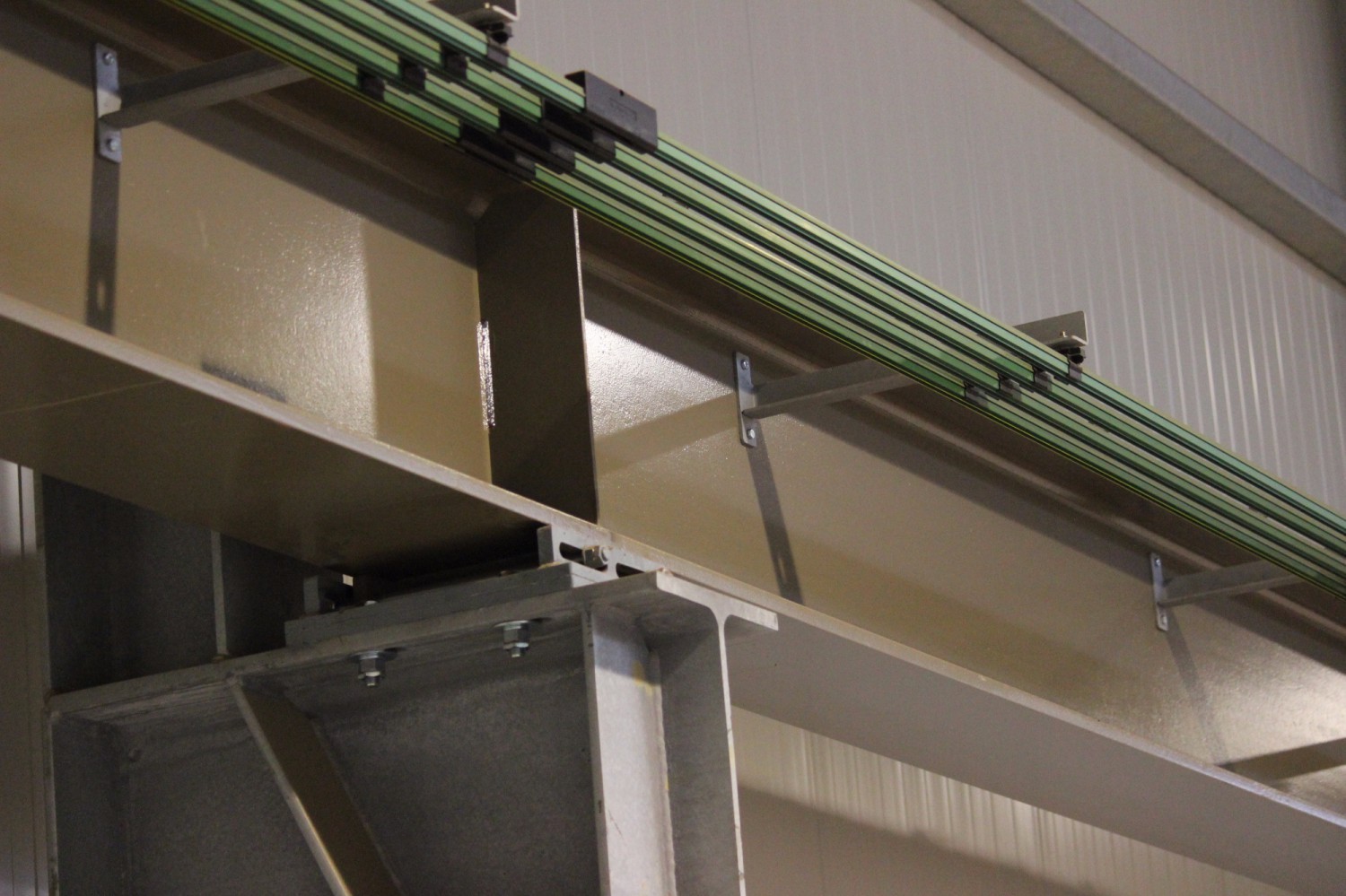

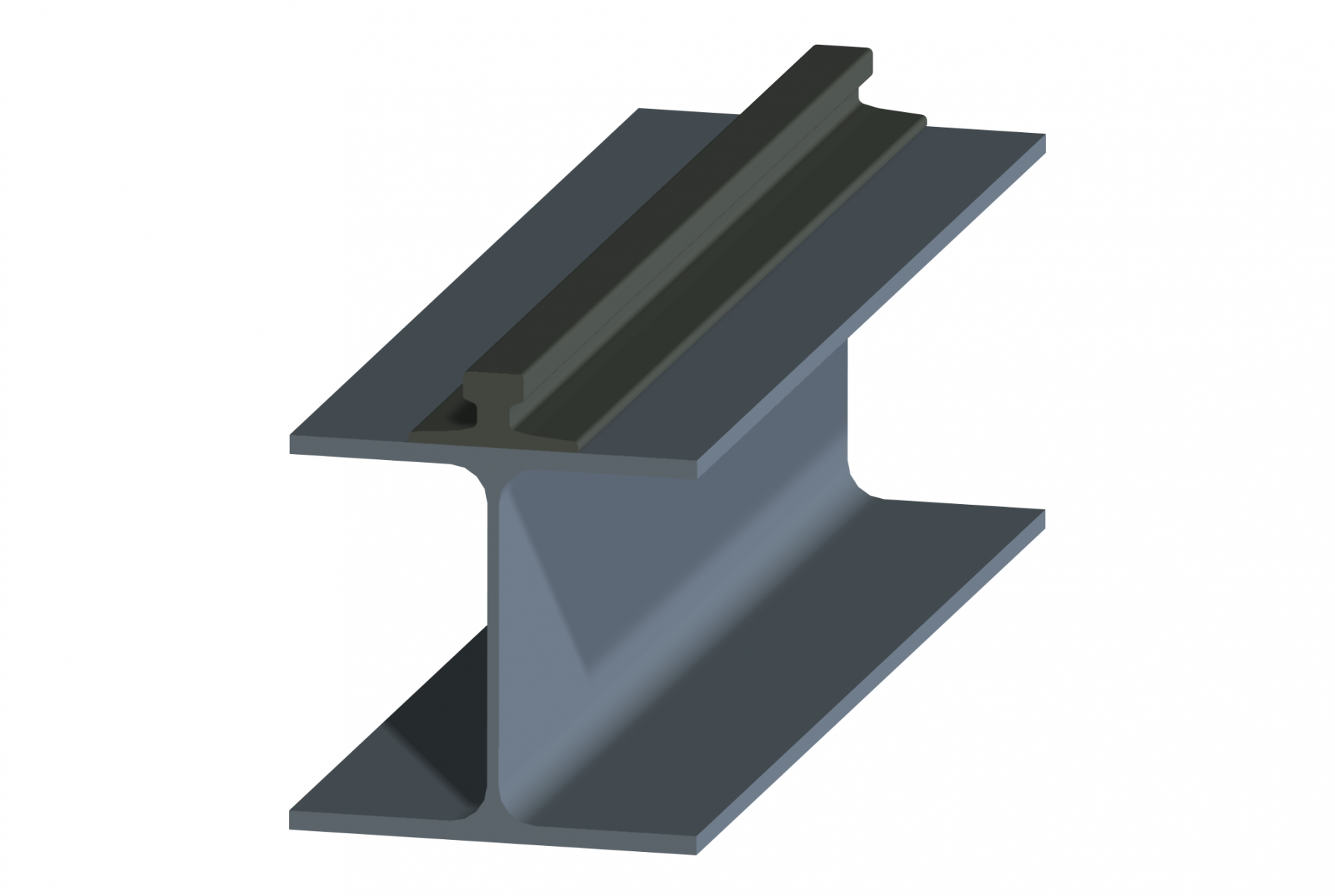

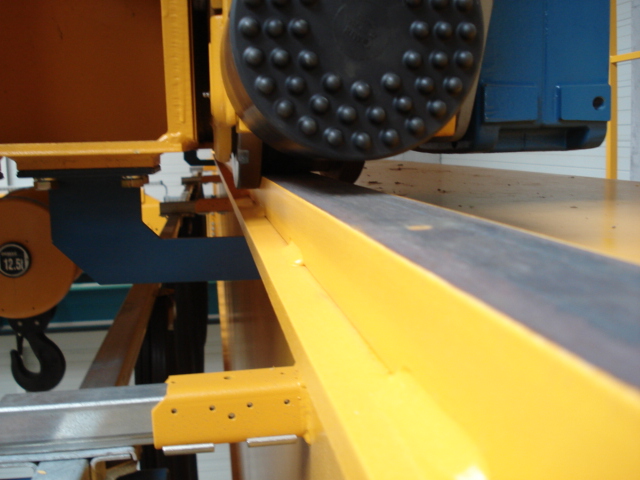

Crane runway beam section

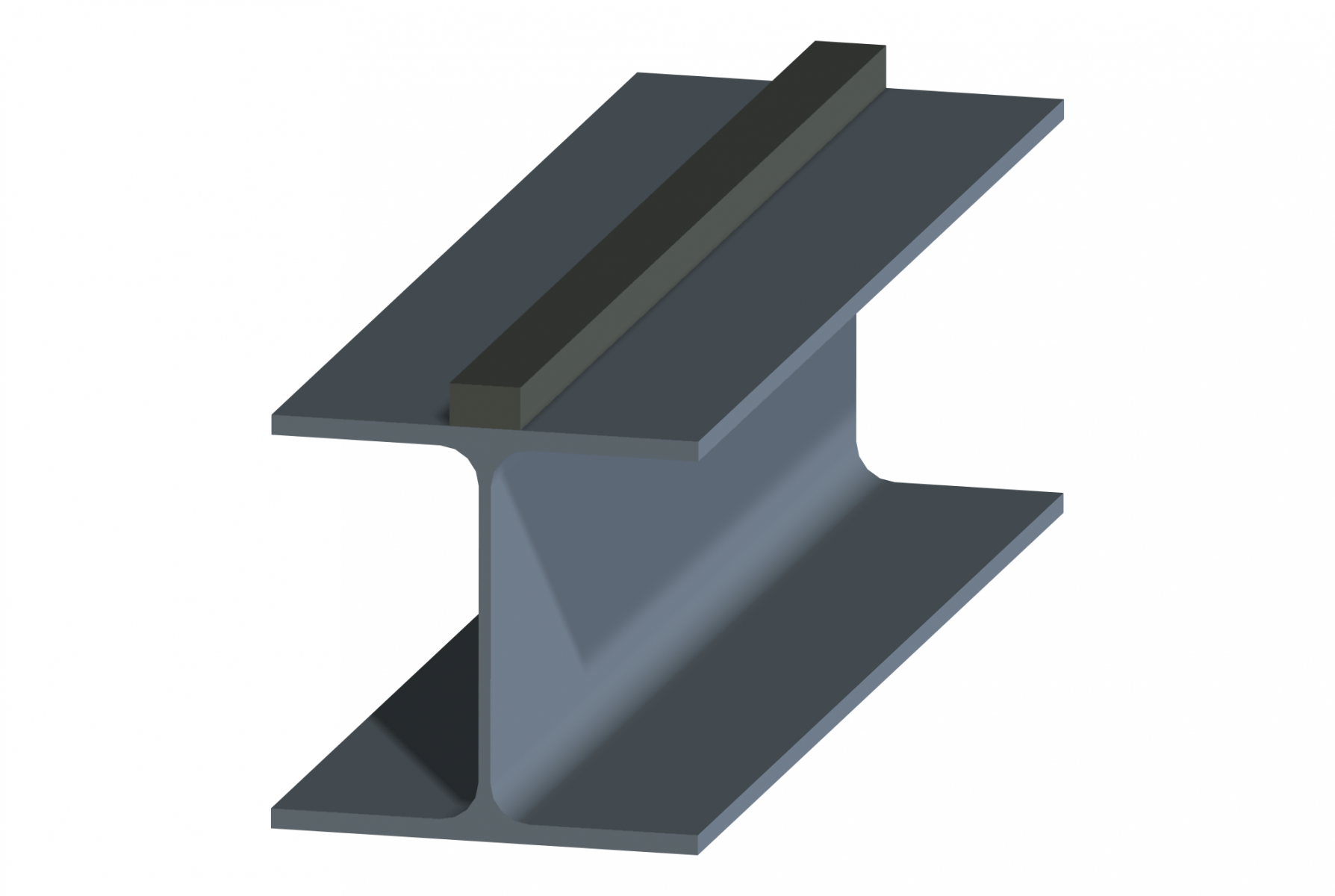

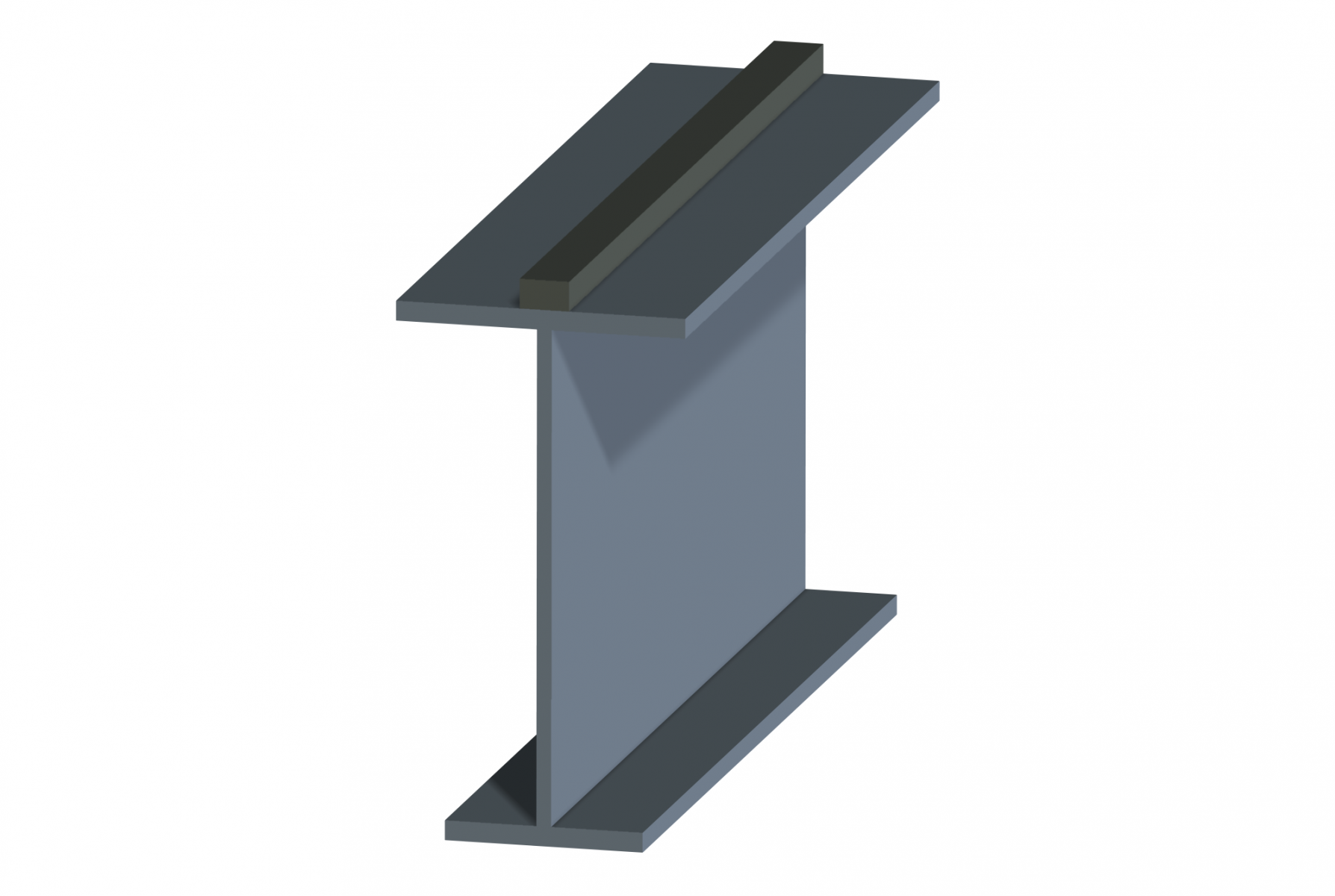

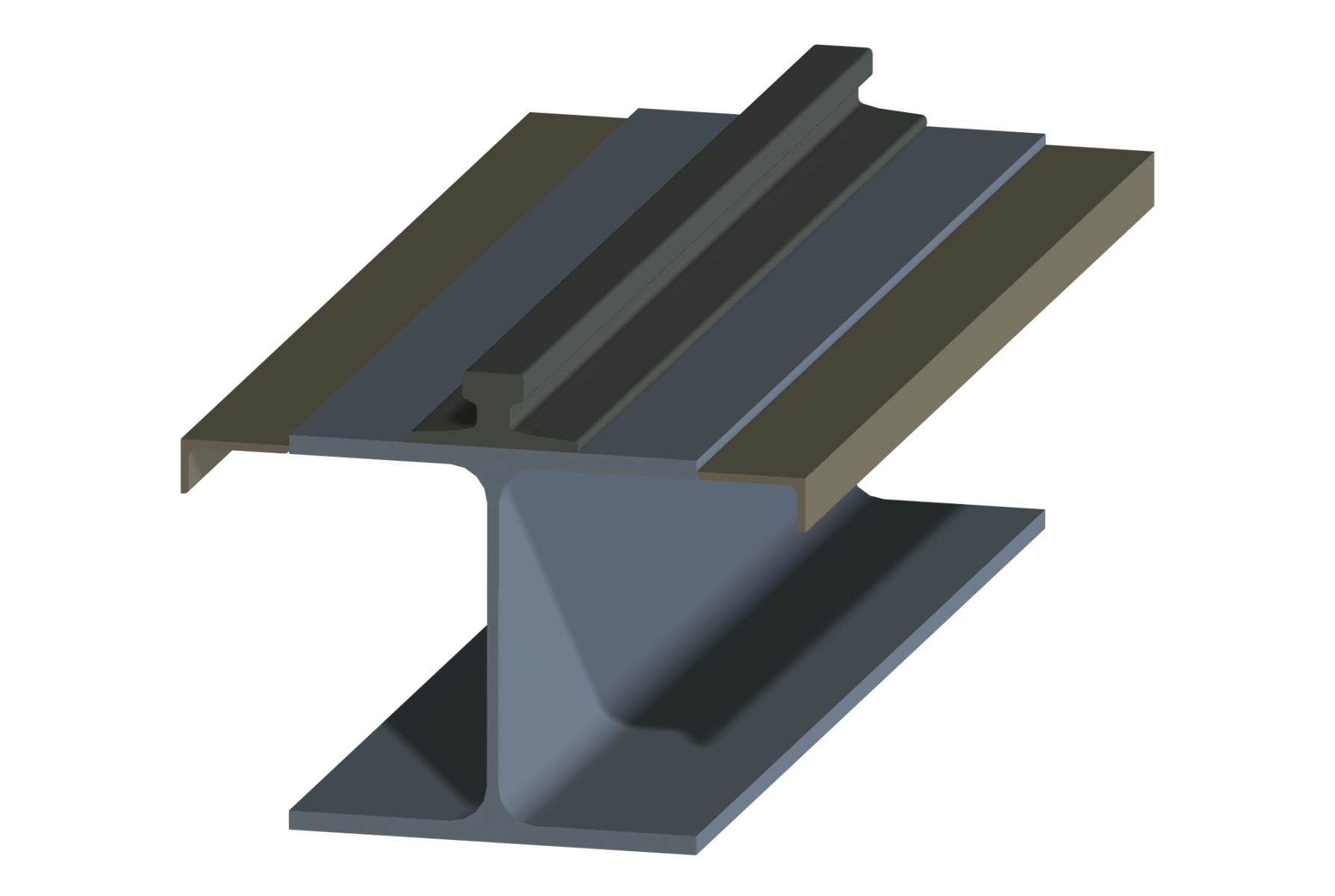

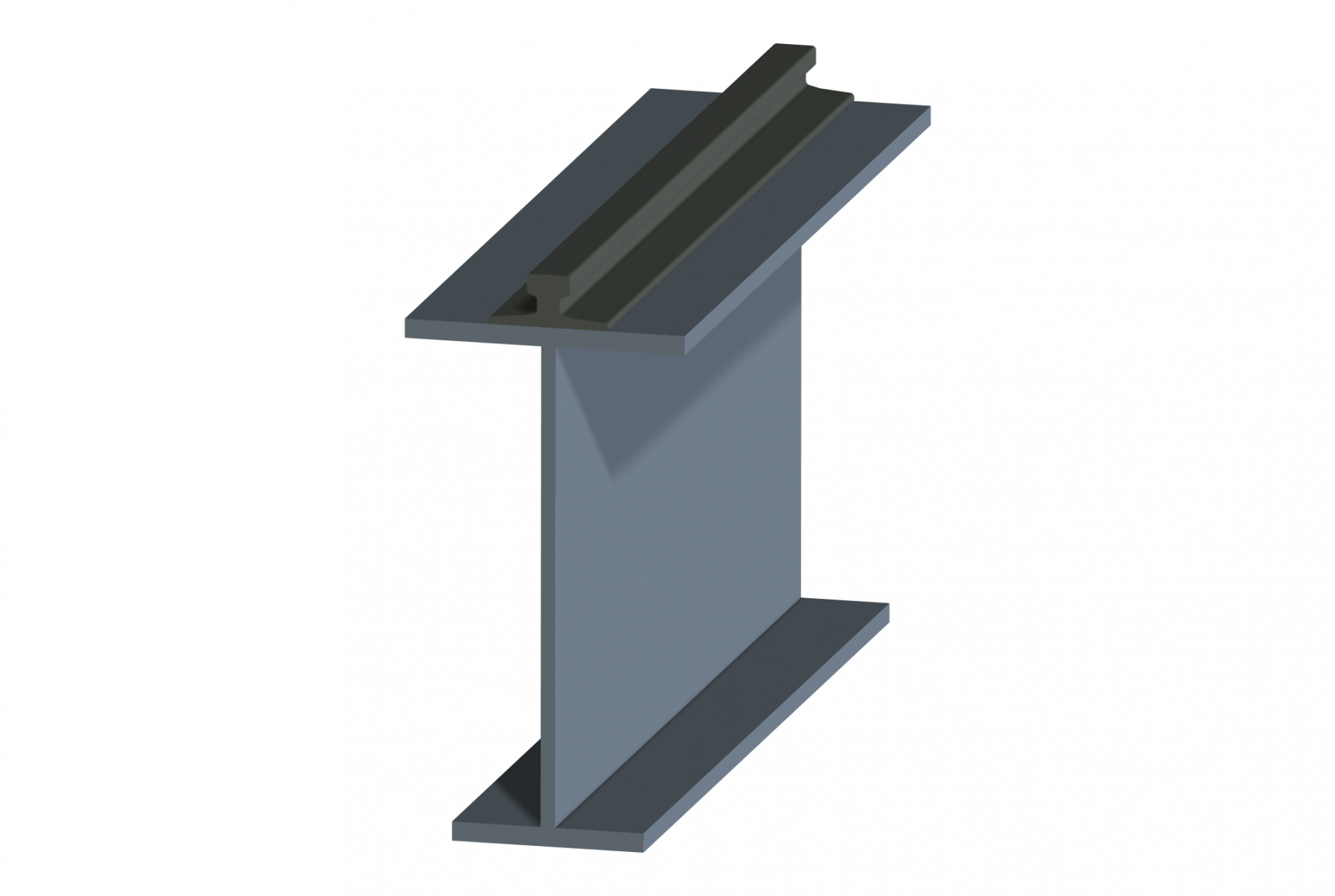

The crane runway beam section of overhead cranes can consist of a rolled I-section, either with or without side reinforcements for supporting horizontal loads, an I-section that has been welded together or a box girder.

|

|

|

|

|

|

|

The same type of sections can be used for suspended cranes, however without a rail. For gantry cranes, we consult with the customer for making an optimized choice, according to the operating circumstances and crane use.

The possibilities include a rail that is welded onto an I-section, or an A-rail that is continuously or discontinuously clamped on top. We will provide you with data on the wheel loads, with which you carry out the stability study for the foundations.

The type of rail on the crane runway beam section is selected depending on the application: This can be a rail plate or an A-rail. The correct dimensions of these rails are also a part of our calculations.

Rail plates

Typical dimensions (W x H in mm) for this are:

- 50 x 30

- 60 x 40

- 70 x 50

These rails are professionally welded to the crane gantry section, using a discontinuous weld. The steel quality of these rails is S355.

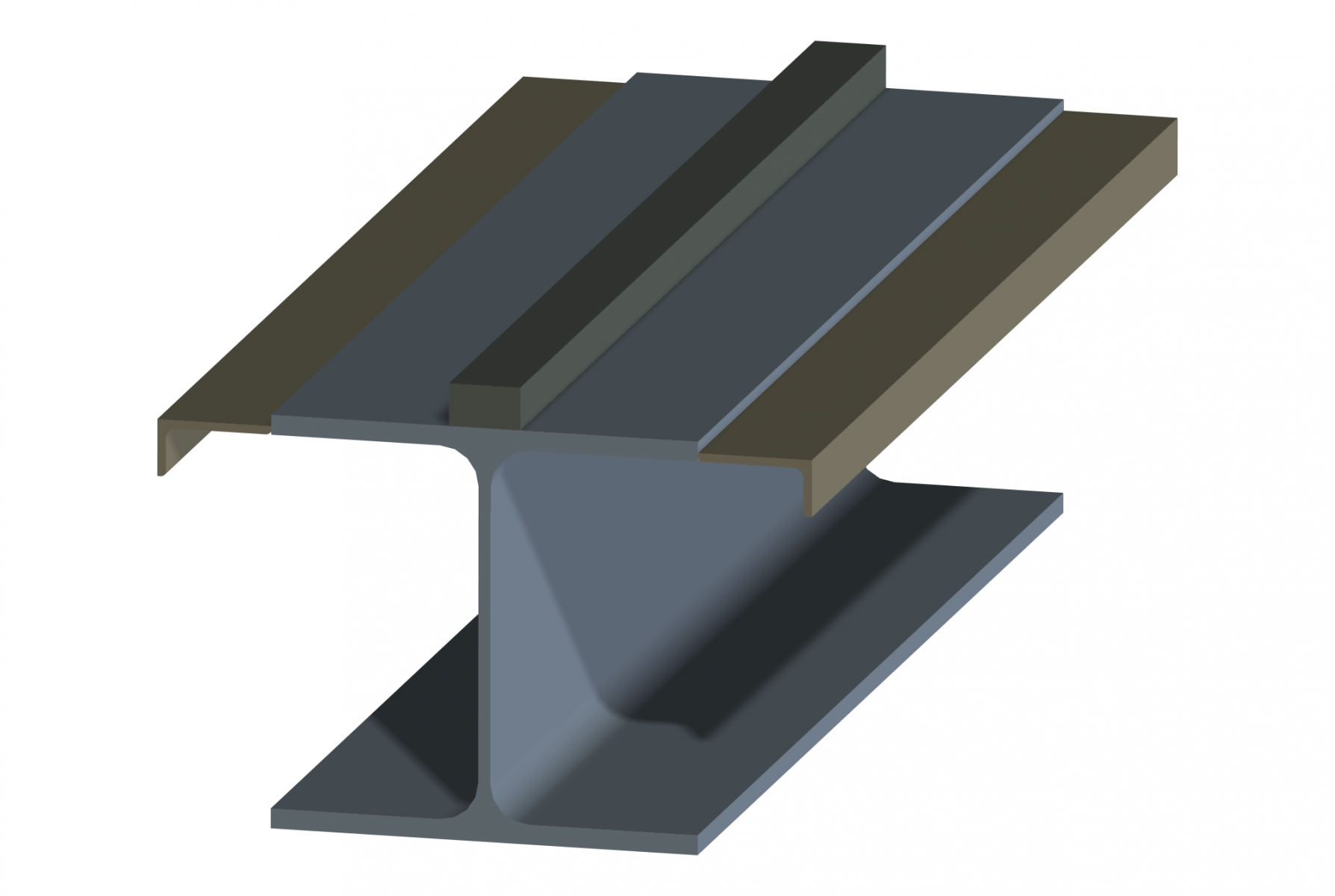

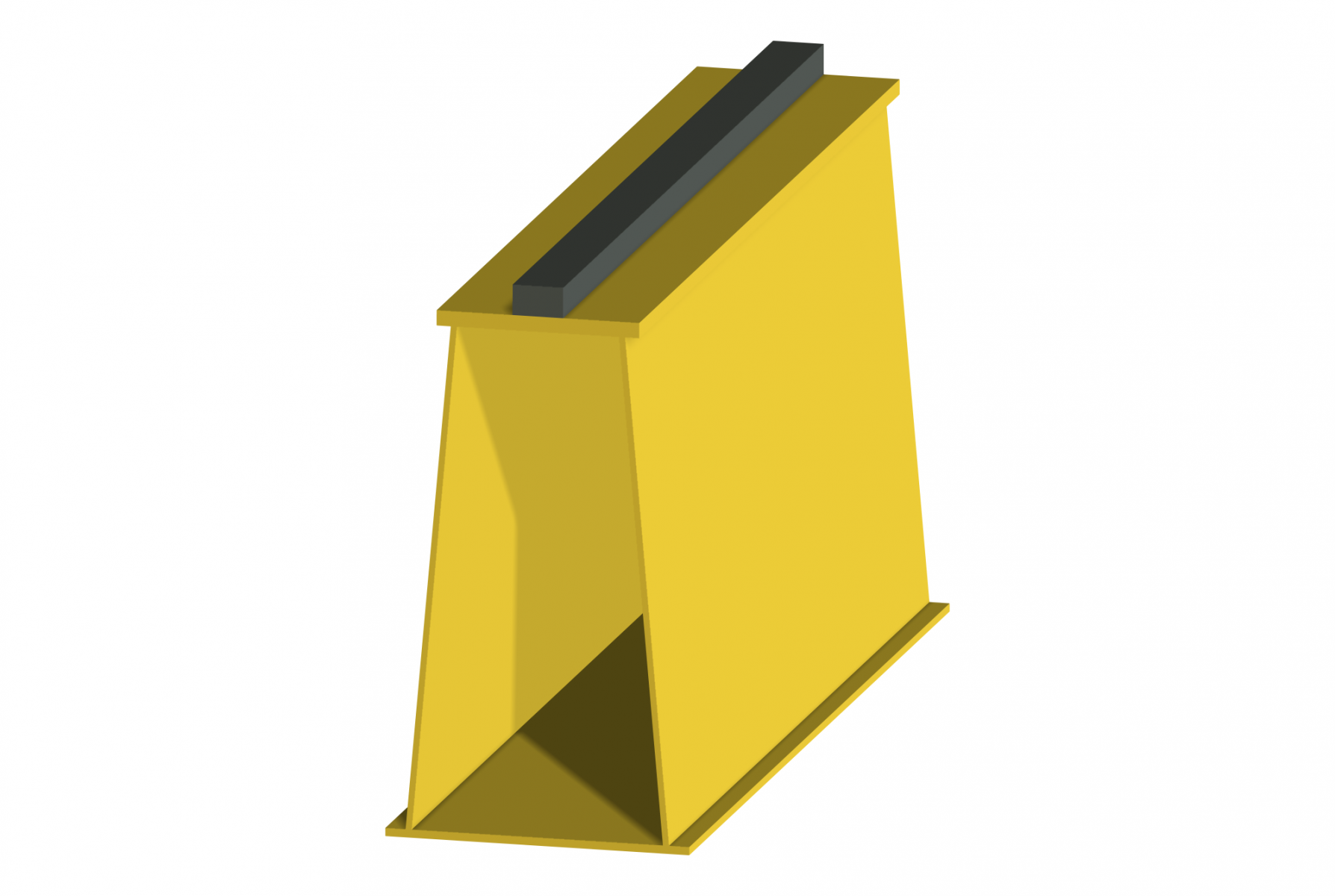

A-rails

These rails are used for larger wheel loads and/or in case of intense use of the overhead crane, such as for intensively used production overhead cranes, which may or may not be automated. They can be used for the rails on the overhead crane, namely for the trolley, as well as for the crane runway beam for the overhead crane.

- The construction form of this rail makes it possible to apply horizontally positioned guide wheels, instead of wheels with flanges.

- The underside has a slightly rounded shape, which means that a suitable, reinforced and elastic supporting mat must be foreseen on the runway section.

- A-rails are usually clamped at regular intervals to the runway profile.

- If the rails are welded to one another, using aluminothermic welding, then you will have a durable and reliable rail solution.